I'm not quite done with Mz. Kit Kat LeNoir's Cloche de Fleurs, but I finally gave it a proper name — Audrey. The cap is a tribute to timeless beauty, Audrey Hepburn. It's worked in Tunisian crochet and Half double crochet — looks like fine silk ribbon, no? I love the slight sheen this champagne colored microfiber.

The hardest part of making this hat is making a composition of anemones, for now they’re just tacked into place. This cloche has gone through quite a few changes so far — I changed the brim twice, I used fewer flowers. So what the hell do i do with a bag of pink flowers? Here’s a quick preview with the brim up and down.

Saturday, April 30, 2011

A Cloche Encounter with Audrey

Labels:

Cloche,

Crochet,

Hat,

Tunisian Crochet

Saturday, April 23, 2011

A Cloche Call

Bell hats at The Bell House? I’m making two floral cloches for Kit Kat LeNoir and Courtney Louvre, chanteuses of the French power-pop band Les Sans Culottes. I’m preping the ladies for a big gig at The Bell House on Thursday, June 2. It’s gonna be a packed night as they play along side with bands Electric Six and Township.

I’m trying to evoke the look of Persian Lamb with champagne colored flowers. I’m also exploring combinations of tradition and Tunisian crochet for these summer beauties. So far I’ve made a bag’s worth of champagne colored anemones and a few sketches.

The cloche (bell hat) was created in 1908 by Parisian milliner Caroline Reboux. The cloche’s popularity grew through the collections of fashion designers like Nina Schiaparelli and Coco Chanel. It's flair became synonymously with the Art Deco movement, Jazz Era music, and flappers of the 1920s.

Worn low to the brow with eyes peeking from under, the cloche conjures the rakish abandon of the 1920s flapper. The fashion houses elevated the cloche into couture, but it was the film and entertainment industry that made it the hat that every woman wanted.

Fashion icons such as Hubert de Givenchy, Roy Halston, Cristóbal Balenciaga, and Christian Dior revived the cloche from their runways to the big screen in the 1950s through the 1970s. Casual elegance was reborn.

I’m trying to evoke the look of Persian Lamb with champagne colored flowers. I’m also exploring combinations of tradition and Tunisian crochet for these summer beauties. So far I’ve made a bag’s worth of champagne colored anemones and a few sketches.

|

| Designer Caroline Reboux (far left), and her signature work. |

|

| Fashion pioneers Coco Chanel (left) and Nina Schiaparelli. |

|

| Evolution of the cloche (l-r): Joesphine Baker, Louise Brooks, Joan Crawford |

|

| Italian screen goddess Sophia Loren from the movie “The Millionaires.” |

|

| Actress Audrey Hepburn sporting Hubert de Givenchy (photos: Sir Cecil Beaton). |

Fashion icons such as Hubert de Givenchy, Roy Halston, Cristóbal Balenciaga, and Christian Dior revived the cloche from their runways to the big screen in the 1950s through the 1970s. Casual elegance was reborn.

Sunday, April 17, 2011

Zuki BlackBerry Caddy

Say hello to Zuki, she’s a cell phone caddy for people who are obsessed with cute. I made her for my new Blackberry Curve — here’s one way to soften the impact of technology.

I used the linen stitch to create a very firm, but flexible fabric. I also finished the trim with a simple crochet border. Zuki is made with ultra soft Misty Alpaca DK, and filled with Azuki Beans — the same beans used to make Red Bean Paste.

She’s handy when recharging my phone or when I have my Blackberry set to alarm clock mode. I like the way her little pink eyes stare back at me when the alarm goes off. I also like squeezing her when I’m on the phone — feels like the best stress ball I’ve ever had.

For most Zuki may not be exceptionally *useful* but she’s packed with Azuki Beans and lots and lots of charm.

I used the linen stitch to create a very firm, but flexible fabric. I also finished the trim with a simple crochet border. Zuki is made with ultra soft Misty Alpaca DK, and filled with Azuki Beans — the same beans used to make Red Bean Paste.

She’s handy when recharging my phone or when I have my Blackberry set to alarm clock mode. I like the way her little pink eyes stare back at me when the alarm goes off. I also like squeezing her when I’m on the phone — feels like the best stress ball I’ve ever had.

For most Zuki may not be exceptionally *useful* but she’s packed with Azuki Beans and lots and lots of charm.

Labels:

Crafts,

Crochet,

Knit Patterns,

Knit PH,

Knitting

Thursday, April 14, 2011

Enamel Workshop Part 3 —

Cloisonné at Liloveve Studio

At the table next to me someone asked “Are you making googly eyes?” My eyes were a bit strained but he was actually talking about my cloisonné strip. This ancient enamel technique is time intensive, but well worth the effort.

Thin flat wire is shaped into small partitions called cloisonnes.These chambers are with filled with glass paste and fired numerous times to achieve a jewel-like affect. Cloisonné requires many firings to build layers of color. So get used to wearing gloves, and don’t wear anything flammable.

Instructor Emilie Shapiro gave us a detailed demonstration. First she prepared a copper base kiln-firing it with an opaque layer of color. This creates a perfectly smooth glass surface. After cooling and cleaning it was brushed with an even layer of Klyr-fire adhesive.

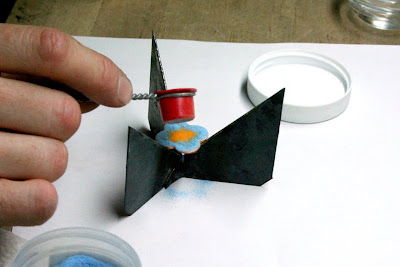

Small cloisonnes made from silver wire are placed in a simple design and kiln-fired. These simples circles were made by wrapping and cutting with needles nose pliers. The Klyr-fire adhesive held them in place but kiln-firing adheres them to the glass.

This small kiln can reach temperatures of over 1500° F. This sample piece was fired for only about minute — the steel trivet turned from dark gray to a bright orange. Immediately after removing from the kiln, the cloisonnes are tapped with a metal spatula to make sure they set into the base layer before it has cooled.

After cleaning the interior of the cloisonnes are wet-packed with a contrasting color of opaque glass paste and set aside to dry, then fired again. This process of firing and wet-packing in and around the cloisonnes is repeated until the glass barely covers the wires. Spills cleanup easily with a paper blotter.

Although I made what appears to be googly eyes, cloisonné has adorned everything from exquisite urns, swords and daggers, and delicate jewelry. The samples below show how this ancient craft has been refined over a long history as it.

I didn’t have enough time to finish my sample, but this is just one small step towards the big project.

To learn more about precious metal and and jewelry making workshops at Liloveve Studio, and to see Caroline Glemann’s work visit her studio website: www.liloveve.com.

Emilie Shapiro is contemporary jewelry designer and metalsmith who received her BFA in Art & Design from Syracuse University. She has studied at Alchimia, a contemporary school of Italian jewelry in Florence, with artist Peter Bauhuis. She managed production at Pamela Love and Allforthemountain and has since launched her own line of jewelry and body adornment. To see more of Emilie Shaprio’s work, visit her website: www.emilieshapiro.com.

Thin flat wire is shaped into small partitions called cloisonnes.These chambers are with filled with glass paste and fired numerous times to achieve a jewel-like affect. Cloisonné requires many firings to build layers of color. So get used to wearing gloves, and don’t wear anything flammable.

Instructor Emilie Shapiro gave us a detailed demonstration. First she prepared a copper base kiln-firing it with an opaque layer of color. This creates a perfectly smooth glass surface. After cooling and cleaning it was brushed with an even layer of Klyr-fire adhesive.

Small cloisonnes made from silver wire are placed in a simple design and kiln-fired. These simples circles were made by wrapping and cutting with needles nose pliers. The Klyr-fire adhesive held them in place but kiln-firing adheres them to the glass.

This small kiln can reach temperatures of over 1500° F. This sample piece was fired for only about minute — the steel trivet turned from dark gray to a bright orange. Immediately after removing from the kiln, the cloisonnes are tapped with a metal spatula to make sure they set into the base layer before it has cooled.

After cleaning the interior of the cloisonnes are wet-packed with a contrasting color of opaque glass paste and set aside to dry, then fired again. This process of firing and wet-packing in and around the cloisonnes is repeated until the glass barely covers the wires. Spills cleanup easily with a paper blotter.

Although I made what appears to be googly eyes, cloisonné has adorned everything from exquisite urns, swords and daggers, and delicate jewelry. The samples below show how this ancient craft has been refined over a long history as it.

I didn’t have enough time to finish my sample, but this is just one small step towards the big project.

|

| Mycenaean bronze sword hilt from grave excavation (c. 16th century BC) Athens National Archaeological Museum |

|

| left: Byzantine cloisonné medallion (c. 1100 AD) right: Ming porcelain (Xuande Period c. 1426-1435 AD) |

|

| Enamel Easter egg from Moscow (Feodor Ruckert c. 1899 –1908). |

|

| Detail: Gilded silver, shaded translucent cloisonné, and guilloche enamel; height 2 1/8 in. (5.4 cm), diameter 1 1/2 in. (3.8 cm) |

To learn more about precious metal and and jewelry making workshops at Liloveve Studio, and to see Caroline Glemann’s work visit her studio website: www.liloveve.com.

Emilie Shapiro is contemporary jewelry designer and metalsmith who received her BFA in Art & Design from Syracuse University. She has studied at Alchimia, a contemporary school of Italian jewelry in Florence, with artist Peter Bauhuis. She managed production at Pamela Love and Allforthemountain and has since launched her own line of jewelry and body adornment. To see more of Emilie Shaprio’s work, visit her website: www.emilieshapiro.com.

Tuesday, April 12, 2011

Enamel Workshop Part 2 —

Kiln Firing at Liloveve Studio

What’s in the oven? Well, it's not biscuits. This small kiln reaches temperatures of over 1500° F. It takes a watchful eye at these temperatures as metal and glass can melt and burn. All the skills we've acquired from torch-firing apply directly to kiln firing.

When working with high heat it’s important to dress correctly. Don’t wear synthetic fibers, wear cotton instead — potential disaster is only a sleeve-length away. Protective heat resistant gloves, tongs and long handled tools are required when kiln-firing — you can forget about wearing flip flops.

Wet packing is another method of applying glass powder by making it into a paste with one part Klyr-fire adhesive and four parts distilled water. After cleaning and buffing a copper surface, the paste is applied with a brush — it's about as viscous as yogurt.

Much like guache or watercolor, the wet paste should be completed in one application and then allowed to dry before further decoration and firing. Many water color effects can be used using the wet-packing technique... blending, gradation, spot coloring... etc.

Sgraffito comes from the Italian word sgraffiare which means “to scratch.” This decorative treatment is used on ceramic tiles, wall treatments, and of course enamel jewelry.

Instructor Emilie Shapiro gave us a detailed demonstration. The finished base color is mars red — first fired, cooled, and cleaned. An opaque blue paste is wet-packed onto the surface and allowed to dry. A design is scratched through the paste with a stylus to reveal the mars red base below, then it’s kiln-fired. Opaque colors are recommended for sgraffito, but transparent layers can be applied afterwards at separate firings.

To prevent warping a layer of counter enamel is applied and fired to one side. Counter enamel is mixed from left-over glass colors. Without a counter enamel, long thin shapes such as this test strip bend like plastic while firing.

In this test strip silver foil is applied, and then layered with more transparent color. Multiple transparent layers deepen in color to create a lustrous surface.

It take a steady patient hand and many trips to the kiln to achieve this gem-like quality. Looks good enough to eat!

Liloveve Studio is owned operated by Caroline Glemann, a designer of fine jewelry. For more information about this enamel class and other classes at Liloveve, and to learn more Caroline Glemann’s jewelry, visit the studio website: www.liloveve.com.

When working with high heat it’s important to dress correctly. Don’t wear synthetic fibers, wear cotton instead — potential disaster is only a sleeve-length away. Protective heat resistant gloves, tongs and long handled tools are required when kiln-firing — you can forget about wearing flip flops.

Wet packing is another method of applying glass powder by making it into a paste with one part Klyr-fire adhesive and four parts distilled water. After cleaning and buffing a copper surface, the paste is applied with a brush — it's about as viscous as yogurt.

Much like guache or watercolor, the wet paste should be completed in one application and then allowed to dry before further decoration and firing. Many water color effects can be used using the wet-packing technique... blending, gradation, spot coloring... etc.

Sgraffito comes from the Italian word sgraffiare which means “to scratch.” This decorative treatment is used on ceramic tiles, wall treatments, and of course enamel jewelry.

Instructor Emilie Shapiro gave us a detailed demonstration. The finished base color is mars red — first fired, cooled, and cleaned. An opaque blue paste is wet-packed onto the surface and allowed to dry. A design is scratched through the paste with a stylus to reveal the mars red base below, then it’s kiln-fired. Opaque colors are recommended for sgraffito, but transparent layers can be applied afterwards at separate firings.

To prevent warping a layer of counter enamel is applied and fired to one side. Counter enamel is mixed from left-over glass colors. Without a counter enamel, long thin shapes such as this test strip bend like plastic while firing.

In this test strip silver foil is applied, and then layered with more transparent color. Multiple transparent layers deepen in color to create a lustrous surface.

It take a steady patient hand and many trips to the kiln to achieve this gem-like quality. Looks good enough to eat!

Liloveve Studio is owned operated by Caroline Glemann, a designer of fine jewelry. For more information about this enamel class and other classes at Liloveve, and to learn more Caroline Glemann’s jewelry, visit the studio website: www.liloveve.com.

Saturday, April 09, 2011

Enamel Workshop Part 1 —

Sifiting & Torching at Liloveve Studio

|

| “Over-fired Cuff”' by Emilie Shapiro (vitreous enamel on free-form copper) |

|

| Sgraffito is a decorative a technique of scratching a wet top layer to create linear designs. |

It helps to have some practical knowledge of metalwork. In this first series of classes, Emilie helped us master the skills and techniques of firing colored glass onto copper by dry-sifting, and wet-packing.

We had our hands full applying layer upon layer yo build a solid opaque surface. Our first project involved sgraffito, an Italian technique in which a design is scratched into a wet layer of enamel to reveal a contrasting color of finished enamel below. It works best with opaque colors.

A copper surface is first cleaned well with denatured alcohol, then buffed dry and treated with Klyr-fire, a cellulose adhesive. Traces of hand grease and impurities affect how well the color covers as it is heated. In this lesson powdered glass is applied by sifting evenly onto the treated surface. Multiple colors can be applied to created an organic gradation but it's best not to blend a new color with this method.

Of course my favorite part of this class was Torch Firing with an acetylene torch. Isn’t that every boy’s dream? This is the most practical way to learn how different materials react to high concentrated heat (“high fire”). You literally can watch metal and glass melt and oxidize. If you're not careful you might melt your project to the trivet — I learned that the hard way.

Work carefully and quickly. As you wait for the copper to turn a bright shade of orange you must also watch the texture of the glass as it fuses. The powdered glass first takes on the texture of granulated sugar as you move the torch around from below. It’s finished when it takes on orange peel texture. When glass is heated to the point of burning it’s called “over-firing.” This effect is similar to raku pottery.

The finished enamel is moved to a clay surface to cool, then is pickled in a low acid bath. More layers can be applied to create different effects as you can see from the examples we made in this class.

Copper is a great conductor of heat, it also has a lower melting point than the steel trivet used for support. Other types of metal for enamelware are fine gold, and sterling silver.

In this studio class we gained a practical knowledge of all tool sand materials for working with enamel. This class has been nothing less than fascinating, but there’s still so much more to learn. Perfecting these techniques lead us to the making cloisonné jewelry. Cloisonné is a Far Eastern technique refined by the French. The word “cloison” is French for partition. This enamel technique involves inlaying different colors into separate compartments made from thin strips of wire. It resembles a painting made from jewels.

|

| In this class I enameled copper buttons to look like mother of pearl and other oxidized metals, clever no?. |

To learn more about precious metal and and jewelry making workshops at Liloveve Studio, and to see Caroline Glemann’s work visit her studio website: www.liloveve.com.

Emilie Shapiro is contemporary jewelry designer and metalsmith who received her BFA in Art & Design from Syracuse University. She has studied at Alchimia, a contemporary school of Italian jewelry in Florence, with artist Peter Bauhuis. She managed production at Pamela Love and Allforthemountain and has since launched her own line of jewelry and body adornment. To see more of Emilie Shaprio’s work, visit her website: www.emilieshapiro.com.

Subscribe to:

Comments (Atom)